This special story attempts

to capture the current

trends in the testing &

measuring equipment

industry. The T&M industry

has never got its due

importance for a host of

legacy reasons. Attitudes

towards the industry are

now changing for the

better, and so is the

outlook for this niche

segment, notes

Venugopal Pillai.

The test and measure (T&M) industry in India is still in

its budding stage. The industry size is nowhere close

to its true potential, and hence presents huge growth

opportunity to its players. In a wide sense, T&M equipment

is used for a variety of applications, mainly including

education, routine maintenance and monitoring, research &

development, manufacturing, and calibration. The sectors

to which T&M is relevant are diverse—ranging from simple

equipment used in educational laboratories to high-end

space research.

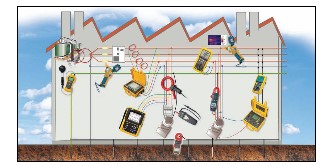

When we look at T&M in the power sector, we are

speaking of a gamut of equipment and services used

spanning the entire power chain—right from a power

generation plant up to the final consumption of electricity.

Even here, T&M is used at both stages-during construction

of the asset and in its regular operation.

A vital segment of the power-related T&M industry is

equipment used in the transmission and distribution

segments. This involves a variety of instruments used to

test and measure the efficiency of power supply and

consumption. The instruments can include simple hand held

devices to sophisticated permanently-installed

monitors. The size of this industry is estimated at around

`700 crore and experts feel that, given the right thrust,

annual growth of around 10 per cent can be easily achieved

in the medium term.

The Indian power T&M equipment industry has

distinctive segmentation. When it comes to common

measuring devices like meters, there are several players with

a predominance of the SME sector. As one moves higher on

equipment-sophistication levels, the number of domestic

players shrinks greatly and there is a marked reliance on imported equipment. In terms of advanced T&M

equipment, there are very few players with 1962-

incorporated Aplab Ltd widely regarded as the domestic

market leader. Multinational players like Fluke, Agilent,

Tektronix, Giga-tronics, Amtek, Exctech Electronics,

Voltech Instruments, etc have a presence in India through

their representative offices and channel partners.

What is calibration? |

Aset of operations, performed in

accordance with a definite

procedure, which compares the

measurements performed by an

instrument to those made by a more

accurate instrument or a standard for

the purpose of detecting and

reporting, or by adjustment, errors

met in the instrument tested. (Source: Shriram Institute for

Industrial Research) Aset of operations, performed in

accordance with a definite

procedure, which compares the

measurements performed by an

instrument to those made by a more

accurate instrument or a standard for

the purpose of detecting and

reporting, or by adjustment, errors

met in the instrument tested. (Source: Shriram Institute for

Industrial Research) |

Industry players point to a growing presence of Chinese

equipment, largely coming from dumping of second-grade

instruments. The market is flooded with low-cost testing

instruments that barely pass the muster. It is also believed

that non-availability of updated industry standardization

and the non-enforcement of existing standards is indirectly

encouraging the import and sale of substandard and noncompliant

equipment. It is not only China but even other

countries continue to treat India as a dump yard for inferior

T&M equipment. An industry player also brought to the

light the growing tendency of small and tiny Indian

manufacturers preferring to deal in imported Chinese

equipment instead of manufacturing their own. Regardless

of quality, Chinese competition is almost invincible on the

pricing front.

There are also tax-related disparities that work against

domestic manufacturers. Most T&D products attract zero

customs duty. Importers pay only countervailing duty. On

the other hand, if the product is manufactured in the

country, key raw materials need to be imported on which

customs duty as well as CVD needs to be paid. Local

manufacturers therefore tend to lose the cost advantage, an

industry player pointed out.

Poor base: The biggest reason of why the power-related

T&M industry in India is still in a fledgling state is perhaps

a non-conducive deployment arena. As a culture, research &

development (R&D) in the power sector has always taken a

backseat. Secondly, India seriously lacks testing facilities.

This inhibits the growth of the T&M equipment industry.

One more factor is that the Indian power sector has never

embraced the culture of regular monitoring of critical

equipment in the power chain. An industry expert

explained that the power chain — from generation to

consumption — has a plethora of equipment. Efficiency in

the power chain can be brought about if the equipment in

the chain is in optimum condition. Periodic checks on the

health of the equipment can prevent breakdowns and

ensure that quality power is delivered. Routine checks can

boost the T&M industry, apart from keep the power chain

efficient, at all times. This is seldom practised in India, the

expert noted.

R&D is not a popular choice of profession and the

government must encourage the younger generation to

considering power-sector R&D as a career choice. While

developed countries have contributed by way of innovative

T&M equipment, it is still early days for India.

Calibration: One of the key determinants of the growth

of the T&M market is strict enforcement of calibration and

testing norms. In India, calibration facilities are perceived

to be inadequate, at least at the moment. More importantly,

the awareness of proper calibration and even testing is low.

Calibration, in simple terms, is the process by which a given

testing instrument's performance is compared with that of

a standard instrument. This ensures that readings of the

instrument are accurate and trustworthy. It is observed

that over a period of time, the readings of T&M instruments

may vary. Periodic calibration is necessary to ensure

optimum performance of the instrument.

Even though facilities for testing and calibration in India

are lesser developed than in developed or even developing

countries, experts feel that there has been perceptible

growth in recent years. Once stringent and unbiased norms

for testing and calibration are enforced in India, rapidity in

the growth of the Indian T&M market is assured.

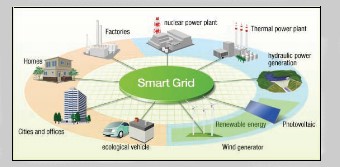

What is Smart Grid? |

A Smart Grid is an emerging phenomenon, currently in vogue only

in highly developed nations. Although there is no standard

definition of the term, it is seen as an assembly of hardware,

computer software and IT-based solutions that aim to bring about

energy efficiency in a power distribution network. A Smart Grid aims

to optimize energy efficiency by reducing energy delivery losses

and balancing load in order to minimize peak transmission

requirements and grid redundancy. It is very interesting to note that

while there has been a big leap in the technology used for building

power generation plants, there is no radical difference in the way

power distribution networks have been built around the world, over

the past century! A Smart Grid attempts to provide a real-time

picture of system conditions so that there is more meaningful

control over the power distribution process. Today, in most cases,

power utilities do not have a real time picture of the system

conditions. This is the biggest challenge. It forces utilities to be

reactive, which is taking remedial action after some damage has

occurred, rather than proactive, which is being able to forestall the

damage by taking preventive action. For instance, the most

common aberration in a power distribution network—power

outages—are known to power utilities only after they are reported.

A concept note by "BPL Global" explains that the key objectives of a

typical Smart Grid would involve digital real-time monitoring and

control of the power distribution network, integrating

communications, transforming the energy meter into a two-way

portal between the consumer and the power utility, and integrating

distributed energy resources. |

Energy efficiency: India's electricity chain is

generally inefficient, seen from many angles.

Infrastructure for transmission and distribution has not

kept pace with new generation capacity. This results in

acute shortages and region-wise disparities. This is only

part of the problem. The bigger problem is that power

supplied to most places is interrupted and unclean.

Uninterrupted and clean power is today seen only in

highly-developed urban pockets. Experts feel that

increased use of T&M equipment could result in

improving at least the quality of power supplied. Right

from the power generation plant to the final distribution

substation, there is a plethora of equipment used. Periodic

testing and preventive maintenance of this could boost

the use of T&M equipment.

Even on the consumption side, much of the power

consumed is done so inefficiently. By and large, industrial

consumers fail to maintain a high power factor ratio. It is

encouraging to note that power distribution utilities are

imposing penalties on consumers that consistently fail to

ensure efficient power consumption, which is measured by a quantifiable power factor ratio. Instruments used to

manufacture power factor ratio can play a vital role in

assessing this situation.

FUTURE READING

The future for the Indian T&M equipment industry is

certainly very bright. This optimism essentially comes from

the country's power sector ambitions. India is set to add

around 15,000 mw of new power generation capacity per

year, over the next 5-7 years. New power generation plants

and supporting evacuation infrastructure will positively

influence prospects of the T&M equipment industry. It is

also pertinent to note that Indian power transmission is

moving to the EHV and UHVAC class, which will generate

demand for even more sophisticated equipment.

The use of T&M equipment is two-fold. The first

application is the construction stage, which is when power

generation and T&D infrastructure is physically built. The

second important application is to ensure that power

infrastructure operates at optimum levels. By 2012, at least

as per targets, India's power generation capacity is expected

to touch 2 lakh mw, nearly doubling over the past decade.

Hence, the power network will get increasingly intricate.

Industry experts say that the future of the T&M

equipment industry lies in real time and remote

monitoring. This is in contrast with current trends that are

identified by equipment-driven and local testing. Hence,

the future trend will be towards computerized data

acquisition, processing and analysis. Computer software

and Internet (IP) based applications will be a big component

of the T&M industry, as we go forward. According to Joey

Joseph, Managing Director, TTL Technologies Pvt Ltd, "PCbased

software that can do advanced analysis and archiving

of data is now common in all new-generation test

instruments." Power quality monitoring and recording

systems are typical examples of web-based applications.

A mature power sector is characterized by the availability

of quality power, on a continuous basis. The T&M industry

will hence aim at helping achieve just this. In an extended

sense, the concept of Smart Grid is essentially a very

intelligent and sophisticated form of testing and

measurement of the entire power chain.

Time-tested Views |

We have to depend fully on imports. Sometimes this becomes a

major hurdle in the development of sophisticated products.

Aplab has so far managed to make indigenous products which remain

an economical substitute for imports, but we know how difficult it

becomes to bridge the gap in technology covered by countries in the

West and the Far-East.

Ms Neelam Kumar, Executive Director, Aplab Ltd

We agree that power sector has given a little bit less emphasis on

having quality T&M equipment. But the scenario is changing

fast with new regulations regarding efficiency, safety and reliability

coming in. This has increased the accountability of people in

business. We expect to have greater penetration of T&M equipment

in the power sector in future.

Suneel Kapoor, General Manager, Industrial Group India, Fluke

State-of-art technology, high reliability and conformance to the

latest international test standards have traditionally been a driver

for Indian customers to look beyond Indian brands. Foreign brands

tend to offer attributes like portability and ruggedness into their

product design and packaging that appeal to Indian customers.

Joey Joseph, CEO & MD, TTL Technologies Pvt Ltd

Some companies in India don't give much importance to R&D as

well as maintenance and re-calibration of the T&M equipment.

This has resulted in lower demand. Probably if companies give more

focus on R&D and on regular maintenance of their plants, demand will

increase.

S. Mahendra Bothra, Managing Director, Microtek Instruments Ltd

(Views are based on exclusive interactions with Electrical Monitor. Full

interviews are presented elsewhere in this edition.)

|