— Richard Cotterell,

Managing Director, Perkins India

— Richard Cotterell,

Managing Director, Perkins India

UK-based Perkins is a group company of Caterpillar Inc and has

been in India for close to 30 years now, supplying engines for

generators and power backup.

Richard Cotterell discusses the

activities of Perkins in India and also shares the company's plans of

putting up a greenfield manufacturing plant with an investment of

$150 million. With 8-10 per cent growth in the electric power

sector, India will be a key market for Perkins' 4000 Series engine,

asserts Cotterell. An interview by

Venugopal Pillai.

What is your view on India's dependence of fossil fuels and the

slow but steady evolution of renewable (inexhaustible) energy

sources like solar, wind, etc?India has traditionally relied on fossil fuels to generate much of

its power and while this is still the case, more investment is

being made in alternative sources of energy. Though these are

environment-friendly and sustainable resources, the projects

are in their infancy, although a number of solar power

applications are finding their way into India.

Indian power grids typically face a dual problem of inadequacy

and also instability. What is your opinion?

Investment is and will continue to be made in infrastructure to

meet the national demand, but as this takes place the gap can

be filled with efficient stand-by and prime power solutions to

keep industry and commerce running and growing.

In view of India's growing and largely unfulfilled energy needs,

how do you see the market for gensets?

The Indian generator set market is a well-organized and highly

competitive space with a lot of growth potential in the future.

This market has and we believe will continue to create a lot of

opportunities for engine manufacturers, as demand for reliable

sources of power are expected to grow considerably. Perkins is

one of the world's leading providers of diesel engines into the

construction, agriculture, industrial, material handling and

electric power generation markets. We expect growth in all

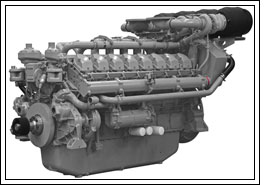

these segments. With eight to 10 per cent growth in the electric

power sector, India will be a key market among the Asian

countries for our 4000 Series engine which we will

manufacture out of our facility in Aurangabad.

While we appreciate that gensets are efficient stand-by power

generators and can stand in for brownouts, what is your view

on the cost efficiency mainly in the Indian context?

In India, fuel efficiency and power density are the most

important factors we have observed, as well as having

appropriate environmental controls over how power is

generated. It is our intent to build world-class products

providing the very best operating costs to those that use them

while at the same time meeting the stringent emission

standards.

Do you think that with perceived improvement in gas

availability and also due to high crude prices, there will be a

change in equations for gas- and diesel-based generators?

We have already seen changes starting to take place in

other countries where gas powered generator sets are

increasing in numbers and we would expect to see gas

powered generator sets becoming more prevalent in India in

the future.

In the Indian context, gensets tend have a different role as

compared to that in developed countries. Can you

elaborate?

In the Indian context, gensets tend have a different role as

compared to that in developed countries. Can you

elaborate?

Standby power in India is very different to that in a more

mature market, with generator sets in standby mode

running for eight or more hours a day when brownouts

occur; a much longer period that normally associated with

that mode of operation. From a technological point of view

that means the engine, which is at the heart of a generator

set, has to overcome the challenges posed by its application,

its location, its installation and its ongoing maintenance.

Reliability is a key requirement and that is why mechanical

engines are so predominant. These engines offer simplicity

yet are extremely robust and capable of withstanding the

challenging environment and conditions often imposed on

them, while being technologically advanced.

We have undertaken a great deal of work on our 4000

Series engines to improve its operating criteria with

markets such as India's in mind. Our most recent engine, the

4016 Series, which will be built at our new facility in

Aurangabad, delivers 10 per cent more power than its

predecessor while the package size has remained the same,

so effectively increasing the power density (kVA/litre). This

has been achieved without having to increase the size of the

cooling pack; instead we have moved to an air to water

charge cooled system that in itself offers greater flexibility

as it can be located remotely.

Tell us about how Perkins maintains environment consciousness

in its gensets.

For 80 years we have worked with generator set

manufacturers to bring light, warmth, protection and peace

of mind to thousands of people. Our range of small, medium

and large diesel engines provides clean efficient power from 5-2500kVA and for gas engines from 300 - 1000 kWe.

As it stands India is anticipated to lead the world when it

comes to imposing regulations for stationery power

applications. In July 2013 the legislation will mandate that all

generator sets under 800kW will need to achieve EU Stage 3A

equivalent emissions levels while generator sets above that

threshold will most likely need to achieve EU Stage 2 equivalent

emissions levels.

While some may view this as yet another hurdle at Perkins

we treat it as an opportunity to improve on what we already

have. It will inevitably take some work around the combustion

and fuel injection processes to arrive at the solution but we

believe we will have the appropriate technologies in place

when the time comes.

The important thing here is that electricity will be able to

be produced more cleanly and with less impact

on the environment.

Early this year, Perkins had

announced plans to set up a

greenfield manufacturing unit

in Maharashtra. What is the

current status?

Early this year, Perkins had

announced plans to set up a

greenfield manufacturing unit

in Maharashtra. What is the

current status?

The manufacturing facility is a

$150 million unit located in the

Shendra Industrial Area in

Aurangabad. Work to level the site is

currently underway with construction

work set to start in mid October. The facility is targeted to open

in mid 2013.

We have already hired our key appointments and continue to

grow our employee base for the plant, as we focus on setting up

a strong team in Aurangabad, lead by a Facility Manager who

will overlook all our operations at the plant.

Initially the facility will have the capacity to produce around

3,000 engines per year with the capability to increase to 5,000

units. The new India plant will serve the growing demand from

the Asian markets. This investment is an excellent opportunity.

We have a really engaged team focusing on delivering the start

up. The first engine from the facility will be manufactured in the

middle of next year. The facility will generate employment not

only in the Aurangabad region but also across the supply base.

What is your business outlook for Perkins gensets in India and

what would be the key business drivers?

Our strategy for growth in India builds on the good work that

we are already undertaking today in partnership with our

valued customers. Working closely with our customers and

providing high quality products are critically important factors

for us. The new India plant will help us manufacture closer to

our customers and serve the

growing demand from the Asian

markets. In addition to

manufacturing our 4000 Series

engine in Aurangabad, we will

continue to offer and make available to

our Indian customers, our wider range of

diesel and gas engines which currently

power more than 5,000 different applications

in construction, agriculture, materials

handling, general industry and electric

power, around the world. We will also be

investing in our brand to support our future growth

plans.

Our initial focus will be to make our plant fully operational,

with construction work starting very soon and an ongoing

recruitment plan to secure our team in Aurangabad. We

continue to focus on and invest in our product support

capabilities in territory and are working with our distribution

network for local media exposure. We will increase our product

offering, relationship building and brand building in the coming

years. By 2016, we expect half of the number of 4000 Series

engines manufactured at Aurangabad, to be exported to the

South East Asian market.