Keshavdas G. Dave, Director – Technical, Indian Transformers Company Ltd

Established in 1979,

Indian Transformers Company Ltd is the country’s largest producer of instrument transformers—both current and voltage transformers—of high and extra high voltages. In an exclusive interaction with

Electrical Monitor,

Keshavdas G. Dave tells us more on his company’s activities and core values. Dave asserts that during the decade to 2022—an important one for the power sector—his company will be firm on its commitment of launching innovative products.

We broadly understand that instrument transformers supply voltage and current to instruments and other power supply control devices. Can you elaborate on the role of instrument transformers in the field of power transmission and distribution?

Instrument transformers act as an interface between the metering and protection functions at the low voltage side and the high voltage transmission line. The role of instrument transformers is very important and therefore there are very stringent guidelines regarding the requirements.

Tell us about the types of instrument (and other) transformers that you produce. Please describe the testing facilities at your Boisar plant.

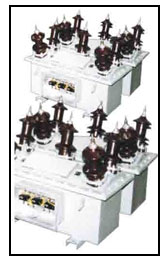

The instrument transformers we manufacture are dead tank and live tank for current transformers, inductive and capacitive type voltage transformers up to 550kV. Recently, we have introduced a new product – single phase combined instrument transformer. While this concept is well known in the developed countries, we are the first company to have a successful installation in India. Recently, we have invested in all the latest equipments for the manufacturing and testing of oil filled instrument transformers.

Given that India would be adding around 17,000 mw of new power generation capacity per year in the foreseeable future, how do you rate the prospects for the instrument transformer business? Are you planning any brownfield or greenfield capacity expansion?

The instrument transformer business is seeing a lot of demand but which is scattered over time. There is no such thing as consistent demand. I have to mention that the demand, although great in terms of numbers over the coming years, is not easy to fulfill because of various constraints on the supply side and also due to slow progress of the various power projects in the country. In that sense, we are yet to witness a boom similar to what happened in China a few years ago in this business. While the capacity side can be increased by the private sector by further investments, the real challenge lies in completing the projects on time, for which the government should take the initiative.

Our capacity, both in terms of numbers and voltage level is steadily increasing. We can already manufacture instrument transformers up to 550kV level. However, 800kV is an entirely different ballgame and we have to be very careful before entering this level.

We understand that power utilities form your biggest and longstanding clientele. Do you notice any change in the procurement policies of power utilities, especially after their trifurcation into “nigams”?

There is some change. Earlier, we saw that there was no clear requirement with respect to specifications. This has definitely improved. Also, there is less financial uncertainty. There is no major change in the policy per se but we certainly think much more is possible now than earlier before the de-bundling.

It is often said that power utilities are bound by the “L1” procurement policy, which sometimes results in the selection of substandard equipment. With increasing private sector participation in power transmission and distribution, do you matters changing for the better?

It is often said that power utilities are bound by the “L1” procurement policy, which sometimes results in the selection of substandard equipment. With increasing private sector participation in power transmission and distribution, do you matters changing for the better?

I don’t think there is an easy answer. The L1 policy is quite sound and justifiable. Why should the customer pay more for a product that meets specification? However, the question to ask is how can the customer differentiate across suppliers? One possibility lies in a score based system which combines everything important like experience, price, quality and delivery. Of course, this should be followed on by a ranking system based on actual performance. It is a tall task. However, it all depends on the customer and their expectations.

In keeping with India’s growth to higher power transmission regimes (765kV, 1,200kV, etc), do you plan to produce higher rating instrument transformers (beyond 420kV) in the near future?

We believe in growing conservatively in the high voltage business. Without sufficient experience at the 400kV level, it would be too ambitious to think of 800kV and above! Of course we plan to grow, but it seems that the government is far ahead of us. Unless we have a few years of experience at the 400kV level, we would not want to jump into 800kV for the sake of it.

We often hear of transformer manufacturers complaining about substandard or scrap CRGO available in the market and also the absence of local manufacturing capacities. What is your view?

This is true. It can be attributed to the lack of knowledge of the suppliers and focus only on profiteering. But there are good alternatives available worldwide and there is nothing stopping a quality conscious manufacturer from getting the best. From a supply chain viewpoint, domestic quality suppliers are few and much needed.

What is your opinion on the alleged lack of testing facilities in India, especially with regard to high-voltage equipment?

I don’t agree to the lack of facilities. There is a lack of suppliers for testing equipments in India. Even in the 21st century, we have to import practically all high voltage testing equipment. There should be a national centre for R&D in the next generation testing equipments for the power sector and incentives and encouragement should be given to develop such niche products for the domestic market. It would also help greatly if the Indian software companies develop world class software for the global testing community.

Please tell us about Indian Transformers’ export business. Which countries/regions would be the major drivers of your exports business?

Please tell us about Indian Transformers’ export business. Which countries/regions would be the major drivers of your exports business?

Under the current global scenario, focusing on the domestic market is most important for us. A good demand for instrument transformers in the coming years could be expected from Africa, South East Asia, and Latin America. There are also opportunities in the developed world, but we have to wait and see how the policy on the smart grid unfolds and contributes to the IT market.

Indian Transformers Co is today the one of country’s biggest instrument transformer company. What major milestones would you like to see the company crossing in the next (say) five years?

Our focus will continue on establishing our firm base across India. We see the decade of 2012-22 as important to the power sector growth and would like to continue with innovative products. Within the next five years, we would like to introduce 400kV combined instrument transformer.