Since the introduction of Alstom's 'advanced-class'

gas turbines in 1995-GT24 for the 60 Hz market

and the GT26 for the 50 Hz market-more than 100

engines have been ignited in KA24/KA26 combined-

cycle power plants (CCPP) constructed

and built on a turnkey basis, a

recent release from Alstom

Power said. The GT24/

GT26 fleet now

has accumulated over 3,650,000 fired operating

hours with more than 64,000 starts under various

operating conditions, be it base-load, intermediate,

cycling or daily start-stop.

The KA24/KA26 products were launched in time to

catch the "Dash for Gas" boom that was seen in both

the 50 Hz and 60 Hz power markets in the second

half of the 1990s. The first GT24 was fired in 1995 in

the Gilbert power station in the US and the first GT26

in EnBW's RDK4 power plant in Germany in 1997.

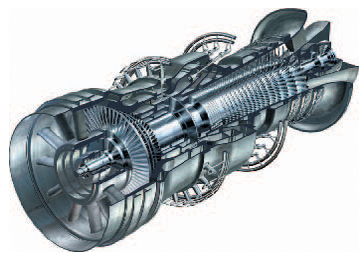

The GT24/GT26 gas turbines were from the very

outset designed to suit specifically the high performance

combined-cycle/cogeneration markets. Its

design features made the engine extremely well suited

for high performance and low NOx emissions

over a wide load range (down to 40 per cent CCPP

load and below). Through this unique turn-down

capability the KA24/KA26 power plants offer very

high operational flexibility. This is particularly suitable

for today's market in which increased power

production by renewable sources require CCPP's to

react quickly to meet the load demand when available

wind or solar output is insufficient. In addition,

the KA24/KA26 technology offers the lowest minimum-

load operating point in the market, with the

ability to park the entire CCPP 'on-line' at approximately

20% plant load, the release noted.

Throughout the last 10-15 years, Alstom has introduced

various upgrades of the GT24/GT26 gas turbines

in conjunction with the KA24/KA26 combined

cycle product offerings, pushing the performanceoutput,

efficiency and part-load capability-upwards,

the emissions downwards and at the same time

meeting the industry's reliability expectations. With

the latest improvements of the

gas turbines and the

water-steam cycle,

Alstom now offers the

KA26 in an integrated

cycle solution with

872 mw net combined

cycle plant

output with 59.1 per

cent net plant efficiency

at ISO conditions*.

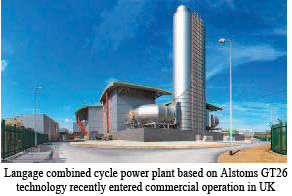

The Emsland

and Langage power

plants, in Germany and UK are

examples. This is among the highest

efficiency levels at base-load for a CCPP

in this class, and a significant step for

Alstom in the path to reach 60 per cent net plant efficiency

with the existing engine platform.

Many new KA26 power plants will enter commercial

operation in 2010

including Emsland in Germany,

Combigolfe in France, Fujairah in the Middle East and Grain

and Staythorpe in the UK. Commenting on reaching this

milestone, Andreas Lusch, Senior Vice President, Thermal

Systems, Alstom Power said, "Alstom's plant integration

capability combined with excellent component performance

and such accumulated experience will ensure competitive

plants continue to be built by Alstom for the world market."

Today, Alstom's KA24/KA26 technology powers over

44GW of electricity globally. The operational KA24/KA26

fleet continues to see high service factors, which is also an

indicator of the technology's inherent flexibility and ability

to adapt to the dynamic power market forces.