Wärtsilä and Aker Solutions

have agreed to combine

their fields of expertise to

develop a new and environmentally

sound concept for offshore wind

farm installation vessels. According

to the contract, which was signed

earlier this year, Wärtsilä will provide

the new installation vessels with the

ship design, electrical power

generation, propulsion machinery

and high-end automation, whilst

Aker Solutions will supply the

jacking system. Wärtsilä, together

with Aker Solutions, will also offer a

24/7 global support service for

maintenance, repairs, and

component supply to the vessels.

The two companies have selected

the best technologies for this custom

designed installation vessel, which

enables a highly efficient way of

setting up offshore wind power

generation. The three Wärtsilä

6L34DF and two Wärtsilä 9L20DF

dual-fuel engines, that will provide

main and auxiliary power for the

vessel, can operate on liquefied

natural gas (LNG) with low

emissions. Similarly, heat from the

engine cooling system will be utilized

to generate drinking water, and to

supply hot water for use by the crew.

The accommodation heating on

board will also use the same heat

source, while absorption chiller units

will provide air conditioning during

summer months.

Aker Solutions has applied its indepth

knowledge of the offshore

drilling market to develop a

continuous hydraulic jacking

system for truss legs, which has

been customized for high

performance turbine installation

vessels. This jack system has great

benefits in regard to redundancy,

and has a robust design for

operations in harsh environments.

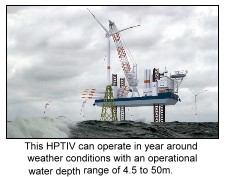

The new vessel concept will be

marketed as a complete package. It

will fulfill the industry's

requirements for large deck space,

sufficient crane capacity, year-round

and all-weather operational

capability and cost-efficient

operating systems.

The market for offshore wind

farms is rapidly developing as

demand for renewable energy sources

increases. Since Northern European

offshore wind farms tend to be in

shallow waters of 50m or less in

depth, so-called jack-up vessels are

used for the installation work. At the

installation site, the vessel lowers

massive legs to the seabed on which

the vessel is jacked-up until it is above

the waves. A hydraulic grip system is

used for this jack-up operation.