In the coming years, India is expected to set a

world precedent - transmitting electricity at ultra

high levels of 1,200kV. Power Grid Corporation of

India, the Central transmission utility, is

spearheading the project with the support of

indigenous equipment manufacturers and service

providers.

Venugopal Pillai attempts to give

an overview of recent developments in this

special report.

Power Grid Corporation of India Ltd,

the Central transmission utility, is

building a test station at Bina in

Madhya Pradesh, to set up a pilot project

to transmit power at 1,200kV levels. The

1-km test line is expected to be completed

by 2012. The results will determine the

feasibility and deployment of this ultra

high voltage technology—currently the

highest voltage at which power is

transmitted anywhere in the world.

Need for UHVAC: India today has

installed power capacity of around 1.7

lakh mw, which is expected to grow by

around 7 per cent annually. By 2027,

India's peak power demand would be 5

lakh mw, necessitating an installed

power capacity of at least 7 lakh mw.

Growth in generation capacity needs to

be matched by efficient power transmission and UHVAC technology is

one means to this end.

Power transmission in India is fraught

with inherent difficulties. First, power

transmission is a land-centric activity. The

geographical footprint of a power

transmission system is far more expansive

than that of a power generation plant.

Securing right of way for a power

transmission project is perhaps the

biggest hurdle in constructing a power

transmission line. The land-related

challenges of a power transmission line

are both topographical (physical) and

emotional. Securing right of way for

transmission lines that pass through

forests or private land is a perennial

challenge. The rationale behind going in

for ultra-high voltage transfer is simple—

when right of way for a transmission line is

in place, exploit it to the fullest.

The second reason why India will need a

sprawling and robust power transmission

network is the fact that power generation

centres are very different from

consumption centres. The eastern and

north-eastern regions are centres for

power generation with highly

incommensurate power consumption

levels. In the case of the northern, western

and southern regions, there is more

consumption that local generation. This

warrants the need for bulk transfer of

power between far-flung regions.

Secondly, India is also planning to import

power from hydro-rich neighbours like

Nepal, Bhutan and Bangladesh. This also

creates the need for high-voltage crossborder

lines, dovetailing with India's

national grid.

The efficiencies obtained by high

voltage power transmission lines are very

striking. A 400kV line can typically carry

400 mw of power. When one moves to

800kV, power transfer between 1,200-

2,400 mw is possible. A 1,200kV UHVAC

line can transfer 6,000-8,000 mw of

power. On the other hand, though, there

are engineering challenges as one moves

to higher voltages. Power transmission at

lower voltages (220kV or even 400kV) is much more manageable that than say

765kV or 800kV.

Industry experts say that building a

1,200kV power transmission line is not

the main challenge. All the equipment—

towers, conductors, transformers,

breakers, insulators, hardware, etc—can

be produced domestically. There is no

dearth of expertise. The main challenge is

the ability to continuously and

consistently keep live a fully-charged

1,200kV line. The performance of a fully charged

1,200kV line will be known only

with time, and this is precisely what is

going to be achieved by the Bina test

station of PGCIL. The test line will

monitor the performance of the

associated equipment over prolonged

"live" conditions. An industry expert felt

that even if India installs 1,200kV power

transmission infrastructure, it will take

some more time before the country is

equipped with fully-charged transmission

lines pressed into continuous operations.

Global scenario: China has been an

active proponent of UHVAC technology.

In January 2009, it set up three

1,100kV power transmission stations

that have been in continuous operation

although it is not known whether the

lines were charged at the highest level.

China has more such lines in the

planning stage. China is a vast country

and the need for bulk transfer of power

over long distances is as acute as

India's. Japan built a 1,000kV test

station way back in 1993 in what is

perhaps the world's pioneering effort in

UHVAC technology. USA and Brazil

are also exploring possibilities of

setting up ultra high voltage power

transmission infrastructure.

A novel PPP approach: India's

1,200kV aspirations represent a unique

form of public private partnership. While

Power Grid Corporation of India is at the

helm of affairs, the endeavour is

supported by around 35 domestic

manufacturers and service providers. The

following is a brief description of some

companies and their achievements in this

path-breaking national ambition.

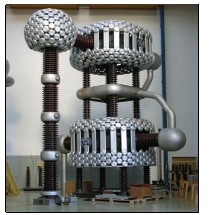

Bharat Heavy Electricals: This Central

PSU engineering major is actively

involved in the 1,200kV pursuit by

providing key equipment. In July this year,

BHEL announced that it developed its

first indigenous 1,200kV transformer of

333MVA rating that will be used at the

Bina test station. BHEL is also involved in

the supply of other key equipment

including 1,200kV insulators.

Crompton Greaves: Thapar Group

company Crompton Greaves in December

last year dispatched a 1,200kV capacitive

voltage transformer for the Bina test

station. The product developed with

indigenous technology at CG's Nashik

plant in Maharashtra was tested at

Central Planning & Research Institute

(CPRI), Hyderabad. CG has promised to

deliver some more equipment including a

333MVA power transformer of 1,200kV

rating and a 1,200kV surge arrestor.

Larsen & Toubro

Larsen & Toubro: In late 2009, Larsen

& Toubro established India's largest

transmission line research centre at

Kancheepuram in Tamil Nadu. The centre

is equipped to test transmission towers of

up to 95m height required for 1,200kV

power transmission lines. This testing

station, according to L&T, enables to

design and validate innovative

configurations without any limitations on

size, shape and magnitude of loading,

which is currently not possible in the

industry due to restriction of available

testing facilities.

Vijai Electricals: This Hyderabadbased

company recently delivered a

333MVA single-phase 1,200kV power

transformer to PGCIL for use at the Bina

test station. The mammoth transformer

was built by Vijai Electricals using inhouse

technology at its Rudraram works

in Hyderabad, Andhra Pradesh.

Areva T&D India: The power

transmission business of Areva T&D India

recently flagged a 1,200kV capacitive

voltage transformer from its Hosur plant

in Tamil Nadu, for deployment at the Bina

test station. Areva T&D India, now part of

Alstom Grid, will further support the

1,200kV endeavour with disconnectors

and digital current transformers.

KEC International: RPG Group company

KEC International has been awarded the

contract to construct the 1,200kV test line

at Bina. KEC has established a tower

testing station at Butibori in Nagpur. Two

towers have already been type-tested and

have been deployed at the 400kV Nagpur-

Wardha transmission line will be eventually

upgraded to 1,200kV levels.

Supreme & Co: Kolkata-based

Supreme & Co has been selected for the

supply of several hardware fittings &

accessories like clamps, connectors,

corona control rings, etc. The company

displayed its 1,200kV product range at

the Gridtech 2011 event held in New Delhi

earlier this year.