—Abraham Varughese, General Manager — Power Quality Marketing, Schneider Electric India

—Abraham Varughese, General Manager — Power Quality Marketing, Schneider Electric India

As part of its holistic energy management company, Schneider Electric offers a wide range of products and solutions for power factor correction, harmonic filtering, etc. In this exclusive exchange with Electrical Monitor,

Abraham Varughese gives keen technical insights into power factor correction and explains that management of reactive energy can make rich contribution to India’s energy efficiency objectives. Varughese also elaborates on Schneider Electric’s future plans that include creating customized solutions for key industrial sectors like oil & gas, cement, steel, textiles, etc. An interview by

Venugopal Pillai.

What are the various products and services offered by Schneider Power Quality Business Group in the area of power factor correction and harmonic filtering?

Schneider Electric offers the most comprehensive range of products and solutions for power factor improvement and harmonic filtering. We have a dedicated department of Power Quality Business, under the Power Business Unit, to take care of this. The solutions include variety of low voltage capacitors suitable for different power quality conditions, automatic power factor correction panels, MV fixed capacitor banks, passive and active harmonic filters etc.

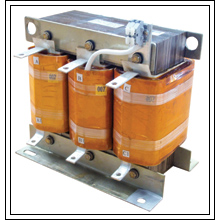

The range of portfolio Schneider Electric offers in India includes VARPLUS LV capacitors, reactors and passive filters, automatic power factor correction relays, LV/MV APFC systems, thyristor-based LV PFC panels, MV capacitor banks, harmonic mitigation solutions, and services that include audit, training and consultancy.

How has been the growth of Schneider PQ Business in India after the takeover of Meher Capacitors in 2009?

How has been the growth of Schneider PQ Business in India after the takeover of Meher Capacitors in 2009?

With the acquisition of Meher Capacitors in 2009, Schneider has significantly reinforced its position to capture opportunities in the fast growing power quality business in India. We now have a unique and comprehensive offer portfolio in the field of energy efficiency encompassing measurement, power quality correction, automation, and monitoring.

We possess the capability of offering end-to-end solutions, starting from consultancy to solutions for any segment of customers—be it an industrial set-up, a commercial building, an electrical utility or in the infrastructure sector

We have shifted our operations to a brand new, state-of-the-art production facility in Bangalore. The LV/MV components and systems are manufactured in this world class facility for global consumption

What have been recent major innovations at Schneider PQ Business?

Schneider Electric recently launched Varlogic Power Factor Controllers with added simplicity and user friendly interface. We also have the very unique, dual setting PF Relays, which will help maintaining desired power factor in EB and DG supply, with one PF panel.

Apart from that Schneider Electric has developed AccuSine range of active harmonic filters which can compensate harmonics from 2nd to 50th harmonic full spectrum, with one cycle response time. This product can operate in harsh electrical environment like oil and gas, port cranes, metal sector, wind and solar farms, marine vessels, etc.

The most recent introduction to Indian market is the PFV solutions, a derivative of the active filters, which can be used for special applications like load balancing, accurate power factor correction etc. at the technology level of the active harmonic filter but at a much lower cost compared to the AHF.

Schneider believes in connectivity and it goes without saying that all these solutions are compatible for communication and easy to integrate with other systems for data acquisition.

How does Schneider PQ Business view the demand for power factor correction solutions in India? What would be major demand drivers?

How does Schneider PQ Business view the demand for power factor correction solutions in India? What would be major demand drivers?

The quality of power is a big question mark today due to the heavy use of non-linear load equipment. This leads to excess energy consumption, losses, under utilization of capacity, breakdown and failures, etc. Hence, it is imperative that the customers will have to go in for power quality solutions for cost optimization as well as to protect costly systems and equipment. This market today is clearly identified as one of the critical elements of the energy efficiency initiatives in India. This is completely in line with the public concern about this issue and has state backing for push on the EE policies in industries, buildings and utilities.

Initiatives like R-APDRP projects are also aiding the demand of capacitors (both LV/MV) in market. Another major initiative on energy efficiency front by Government of India is the PAT (Perform, Achieve and Trade) scheme that also will increase the demand for power quality solutions. There is an increasing trend in the country by different utility companies to adopt the kVAH-based tariff, which calls for maintaining power factor close to unity.

The market is gradually shifting from standard duty capacitors to heavy duty capacitors and capacitors with series reactors with deteriorating power quality conditions. Harmonic mitigation solutions are also finding increased demand in the market as percentage of the non-linear loads on the grid in increasing.

Active harmonic filter which holds top position in the optimum band of the solutions is finding wide range of applications as it offers the flexibility in ratings and point of connection.

We also find an increase in requirement of hybrid and broadband filters in Indian market predominantly for localized harmonic solutions to optimize the capital expenditure.

Please explain in simple terms what power factor correction is, and how it is related to efficient power consumption.

For various loads like induction motor, induction furnace and intermittent devices like transformers, magnetic field is essential for their operation. In order to generate this magnetic field and enable their operation, reactive power is drawn from the grid which in turn loads the power generation, transmission and distribution system.

Power Factor (PF) is the ratio of True/Active Power (KW) to Apparent/Total Power (KVA). If Reactive power drawn from the system is higher, KVA will be higher; hence lower will be the power factor of the system.

By installing capacitors, system can be relieved from the burden of carrying reactive power as the same will be provided through capacitors.

By improving the power factor, the efficiency of generation, transmission and distribution system will improve by reducing the losses and reducing loading on the network, thereby reducing the energy bill.

We understand that even modern gadgets that use induction motors result in reactive energy. Please explain this phenomenon and how the situation can be remedied?

We understand that even modern gadgets that use induction motors result in reactive energy. Please explain this phenomenon and how the situation can be remedied?

Yes, as explained earlier, rotating magnetic field is essential for the operation of an induction motor. In absence of the rotating magnetic field, rotor will not be able to generate the torque, in turn, failing to rotate. In order to generate magnetic field reactive power (kVAR) is essential.

However, it is essential to understand that kVAR does not contribute to the output power available from the motor.

Hence, even though it is essential for the motor operation, it does not result into useful output power. In other terms, we can call it as an essential devil in the system.

In any uncompensated system, kVAR is drawn from the grid. If there are too many uncompensated loads in the system, it will increase burden on the system, in turn reducing effective utilization of the alternators, transformers and distribution lines.

User can decide to improve PF by connecting capacitor across terminals of the motor, thereby reducing the line losses as minimum as possible. However, this is not always advisable as it increases the maintenance load substantially.

If the rating of capacitor connected is sufficient to meet the actual reactive power demand of the motor, the total/apparent power will get reduced to the value of active/true power there by achieving optimum PF in the system.

Schneider Electric is synonymous with “energy efficiency”. Please explain how Schneider PQ Business dovetails with other groups towards achieving the overall objective of energy efficiency?

As an energy management company, Schneider’s goal is to make energy more safe, efficient, reliable, productive and green. It focuses to provide energy efficiency solutions that can help consumers make the most of their energy, thereby turning energy saving into growth initiatives.

Schneider’s PQ Business is no different from the above vision of the company by:

- Making customers more energy efficient by minimizing the transmission and distribution losses

- Safe and Reliable by ensuring optimum capacity utilization of the network

- Productive by minimizing the impact of unwanted harmonics and other power quality issues in the system, ensuring the energy is utilised to do the actual work

We understand that controlling reactive energy is directly and significantly related to saving in electricity costs. Please discuss this in the context of a country like India that is a big consumer of electricity as well as an energy-deficient nation.

Untitled Document

Power Factor |

Increased available power |

|

0.700 |

0% |

|

0.800 |

+14% |

|

0.850 |

+21% |

|

0.900 |

+28% |

|

0.950 |

+36% |

|

1.000 |

+43% |

|

A high power factor optimizes an electrical installation by allowing a better usage of the components. The power available at the secondary of an MV/LV transformer can therefore be increased by improving power factor at the low voltage side of the transformer.

Above table shows the increased incremental available power at the transformer output by improvement of power factor from 0.7 to 1. Hence, with the same installed power generation capacity, more kW can be supplied if the PF is improved.

In a country like India, we have a very large electrical network supplying power to the corners of the country. Very often, we find the capacity is becoming insufficient to handle the ever increasing power demand, especially in rural feeders. Hence, it becomes very important to make use of the available capacity of the network in the most optimum manner.

Moreover, India is one of those countries with high T&D losses, again due to the very large network it has. Maintaining higher power factor in the system will ensure the T&D losses are minimized, making higher power availability to the consumers.

Even in urban situations, one of the major problems we are facing in India is peak load demand and inability to meet the same. Improvement of power factor will lead to reduction in kVA demand and hence will help in taking care of the problem as far as system capacity is concerned, if not the actual load conditions.

The cost saving will be more decisive and important in case of the DG Sets driven plants. The efficiency of the DG sets depends largely on the loading on the engine and with higher power factor of the system, we can ensure optimum loading of the engines leading to better efficiency and better units per liter realization, which has direct impact on the generation cost.

Please discuss in brief the future plans of Schneider PFC in India, in terms of new products, tapping newer market segments etc. In terms of offering to customer Schneider Electric intends to:

- Offer low-voltage and medium-voltage APFC panels in all standard version and ratings thereby optimizing cost with the best solutions

- Improve focus on advanced PQ solutions like active harmonic filters, hybrid filters, which enable harmonic free electrical environment and reduction of losses

- In terms of segments, Schneider is putting special focus to design and develop solutions specific for the textile, cement, steel, water treatment and oil and gas sectors

- Increased focus on providing end-to-end power quality solutions to customers, starting from consultancy to solutions and finally, annual maintenance contracts to ensure sustainability of the solutions