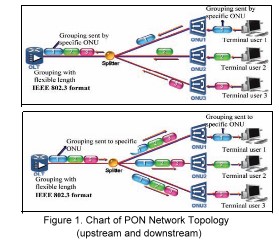

As the deployment of

Fiber to the Home

(FTTH) technologies

in the access network

accelerates, Passive Optical

Network (PON) has become

area of focus among global

broadband operators and

been regarded as one of the

best method. It consists of

Optical Line Terminal

(OLT), Optical Distribution

Network (ODN) and Optical Network Unit (ONU). Its

relatively simple and transparent network structure which

makes it to be commonly used broadband access technique.

The ODN shares more than half of the total initial

investment of FTTH deployment. Its quality of planning

and construction will have tremendous impacts on the

future costs of mass operation and maintenance. ODN is

currently the focus of operators from all countries,

especially in Customer Premises Network (CPN), i.e. in the

last 100 m of fiber access.

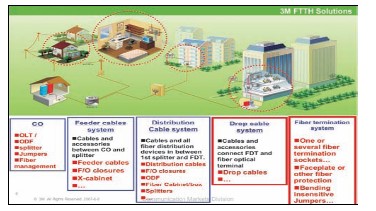

3M is the first advocator and implementer of FTTH

solution worldwide. 3M has leading edge products and rich

experience in fiber connection technology.

ODN structure involves connectivity to various types of

buildings like Residential, Commercial buildings or

Industrial park that requires differential treatment in

design and deployment.

No matter what kind of building type, FTTH network based

on PON can be divided into five parts: (1) Subsystem of optical

fiber terminals (2) Subsystem of lead-in optical cable (3)

Subsystem of optical distribution cable (4) Subsystem of trunk

optical cable (feed line) and (5) Subsystem of central

machinery room.

These subsystems address the requirement from access

room where OLT is placed to the user where ONU is located.

CORE CONCEPT OF ODN DESIGN

3M has found out through its knowledge of domestic fixed

operators network and deploying capability that in the

construction of basic network, the operators are mostly

concerned about the subsystem of optical fiber terminals,

subsystem of lead-in optical cable and subsystem of optical

distribution cable in ODN structure.

Considering the concerns of domestic operators, factors

like basic network structure, and its core technology and

products, 3M put forward the following 4 core concepts for

ODN deployment:

Concept of fiber termination: Optical fibers are required

to be terminated and protected in the socket no matter

where they are (just like the termination of telephone line,

copper data line and coaxial cable for cable TV).

On-site termination of optical fiber: In CPN and user's

rooms, the fiber plugs and sockets shall be made on-site

instead of the traditional pigtail/patch cord of fixed length

made in factory.

Application of fiber mechanical connection technology:

In CPN and user's rooms, the fibers shall be connected by

mechanical connection instead of fusion splicing so as to avoid high investment & maintenance costs, and enable

quick connections.

Adopting special FTTH optical cable: Special optical cable

for FTTH should be adopted to ensure the flexibility, security,

and reliability of wiring in buildings and indoors.

The purpose of the four concepts is to make the

design, implementation, maintenance, and service of

fiber lines as convenient and reliable as those of copper

cable system.

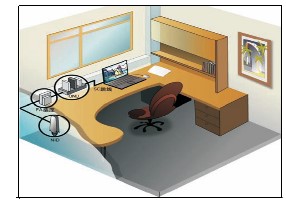

SUBSYSTEM OF OPTICAL

FIBER TERMINALS

The fiber terminal subsystem include one or several fiber

termination sockets, and fiber patch cord connected to the

terminal device (ONU) with super flexural and pressure

resistance to avoid damage to cables and to human bodies.

On-site SC connector is fixed without processes of

glue injection, heating, or polishing. It is advisable to

retain at least 100cm long optical cable in the socket for

future maintenance.

3M's has specially designed fiber terminal sockets 86-

type and 120-type which are widely deployed all around

the world for such applications.

The Glass/Glass Polymer (GGP) super strong fiber

patchcord technology of 3M Company has outstanding

resistance against external mechanical force. There is no

bending loss induced when the diameter is decreased from

15mm to 6mm.

For commercial buildings, there might be uncertainty in

business requirements and high possibility of

modification. It is suggested to follow TSB-75

International Standard. The socket is recommended to be

installed 30cm above the ground & should be at least one

fiber terminal socket in every 10 to 100 square meters or as

per actual requirement.

For the residential apartments, the optical distribution

cable should be installed in the distribution box on the

building corridor (the corridor distribution box is defined in

the distribution subsystem) or other distribution facilities.

Flexible connection or fixed connection can be used in

corridor distribution box to connect the optical distribution

cable with the lead-in cable. Mechanical splice is

recommended for fixed connection.

The mechanical connection does not need welder. It

only uses simple tools and realize the permanent single

core or multiple-core connection by mechanical

connection technology.

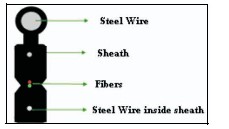

SUBSYSTEM OF LEAD-IN OPTICAL CABLE

The subsystem of lead-in optical cable is composed of cables

and accessories connecting the user's fiber terminal socket and

the building's distribution equipment.

The lead-in optical cable will be connected to the optical

fiber terminal socket in the way of on-site termination. The

lead-in cable would have of small bending radius (15mm) to

route around the corners and it is recommended to be made of

ITU G.657A optical fibers.

Optical distribution cable can also be directly lead-in into

the room in the insertion for some villas or independent users.

In this circumstance, there is no distinction between optical

distribution cable and lead-in optical cable.

The lead in cables has special construction like rubber

covered optical self-supporting cable with steel core or without steel core. In terms of number of cores, it can be

divided into single core, 2 cores, and 4 cores, 8 cores cables, of

which the 2 cores, 4 cores, or 8 cores are distinguished by cover

of different colors. As for the performance, its pressure

resistance and tensile strength are all better than the loose

sheath and tight sheath optical cables that are widely used

now a day in the field.

SUBSYSTEM OF OPTICAL

DISTRIBUTION CABLE

The distribution subsystem is composed of the distribution

box at the corridor (for villa and other independent user, it

may refer to other optical fiber distribution equipment),

optical cables that link the building distribution box and

optical distribution points, optical splitter and cable

connecting accessories.

The optical distribution point is where the optical splitter

locates. A splitter is fiber optic network component that

combine multiple optical channels or divide a single channel

into two or more channels. A single optical channel is split into

32 or more individual channels, each carrying the same

information. In PON, single or two level splitting can be

adopted. Along the downstream direction, the section from

the starting point of the first splitter to the starting point of the

second splitter is the first level distribution subsystem. Section

from the second splitter to the building distribution box is the

second level distribution subsystem.

Designing of splitters takes into consideration of balancing

all the factors such as the initial investment and maintenance

costs, and be based on the principles of easy to implement and

test collectively, saving optical cable resources, saving the

work amount of opening and canceling a user, easy for

maintenance insertion and failure detection, etc. It is

recommended that the splitter shall be as close to the user as

possible. The optical splitter shall be linked to the optical

distribution cable by flexible connection method.

The position and volume of optical distribution facilities

such as distribution box at the corridor should be planned

rationally taking into consideration of current and future

connections & according to the building structure. The optical

cable shall be connected flexibly or fixedly inside.

SUBSYSTEM OF FEEDER OPTICAL CABLE

The feeder optical cable subsystem includes the optical

splitter, optical cables of central machinery room, and other

accessories. These accessories include the cable terminal box

that links and distributes the feeder optical box, the optical

cable cross connection cabinet, distribution box, ODF, etc.

SUBSYSTEM OF CENTRAL

MACHINERY ROOM

SUBSYSTEM OF CENTRAL

MACHINERY ROOM

The central machinery room is configured according to the

access network room. The subsystem of central machinery

room mainly includes OLT and ODF as well as the relevant

devices and optical fiber management system. If optical

splitter is installed on the optical fiber distribution rack, the

connection of splitter outlet and feeder shall be flexible for easy

test and management.

To conclude designing of optical distribution network

(ODN) plays an important role affecting the cost of delivery

and flexibility in providing the connectivity. Careful

consideration has to be given in choosing the products which

are scalable, ease of installation and cost effective.

About the author: Navin Jacob Mathews is General Manager-

Communications Market Division, 3M.