The Stuttgart-based Lapp Group demonstrated its

power for innovation with impressive e-mobility

solutions at the Hanover Fair. The big draw at the

stand was the Lorinser Easybrid®, a car that had been

converted into a hybrid vehicle by the Swabian tuning

specialist, without any alterations to the engine or the

gearbox. With this Easybrid®, the Lapp Group showcased

how easy refuelling would be in future with the LAPP

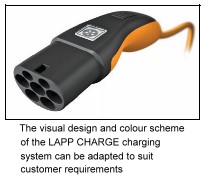

CHARGE system. The innovative charging system, which

was developed together with Bals Elektrotechnik GmbH

from North Rhine-Westphalia, did win over customers with

its ergonomic design and numerous safety features. The

design and colour scheme could be adapted to the

customer's needs, for instance by adding the manufacturer's

logo to the vehicle. LAPP CHARGE meets the VDE

standard, which was defined with input from several

renowned automotive manufacturers.

Lapp also displayed a range of charging variants that are

ready for series production. A spiral cable can also be used as

a connecting cable. This is halogen-free, flame-retardant,

oil-resistant and suitable for use in temperatures from -40°C

to +90°C. Those specifications make it perfect for use in

harsh conditions. Werner Becker, CEO of Lapp Systems,

part of the Lapp Group, said: "This kind of cable must

function reliably in all weather conditions. In addition, it

shouldn't be possible to drag it inadvertently across the

ground when recharging or to damage the vehicle with it.

That is why we are offering this charging system as a

bespoke solution and recommending the use of special,

flexible spiral cables."

The complete connector series comprises plugs and a

range of different flush-mounted socket designs. In the

future, additional contacts in the connectors will be used to

exchange data between the vehicle and the power supply.

In addition to products for the charging infrastructure,

Lapp also provides high-voltage cabling for the next

generation of vehicles. These high-voltage cables are used in

the vehicle interior and can be customized using different

connection technologies. Lapp also has its own patented

connection solution for use in this sector.

New industrial connector:

New industrial connector: The new EPIC® ULTRA

has a modern appearance and a high-quality, shiny

surface. This innovative new development in the field of

EPIC® industrial connectors was presented for the first

time at the stand of by the Stuttgart-based Lapp Group at

the Hanover Fair.

The rectangular connector housing is absolutely

scratch, impact and corrosion-resistant, making it ideal

for use in harsh conditions, e.g. on offshore wind turbines

and biogas power plants. When combined with the

SKINTOP® Brush screwed cable gland, the connector is

absolutely EMC-resistant, as the nickel-coated housing

forms an all-over metallic shell that functions like a

Faraday cage. This is especially important for the

transmission of sensitive BUS signals.

The new housing

combines a number

of advantages: the

SKINTOP ®

screwed cable gland

is built into the

shell, which

guarantees the best

possible sealing and

strain relief, and

also allows fast

assembly, as the

SKINTOP® does

not need to be

screwed in

separately. The lip

seal between the

hood and the

bottom part of the

housing is inset to

provide better protection against mechanical damage. The

seal in the panel mount base that connects to the wall seal is

also a built-in part of the housing. This prevents losses

while also making installation easier. In short, the new

housing protects the sheathed, shielded cables and the

connector even better than before.

The new EPIC® ULTRA is slightly smaller than the old

die-cast aluminium model and an even better fit, thanks to

the thinness of the die-cast zinc walls. This gives developers

and designers more room to play with, as the trend towards

increasingly smaller products is also prevalent in the

mechanical and plant engineering sectors. The clamping

brackets are made of high-resistance stainless steel.